Done debaz yo

Kalite debaz:

1.Izole sèl kondiktè style

2.Twin stil kondiktè

3.Un-izole kòd fen manch

Karakteristik

Total kwa-seksyon: 0.25 ~ 150mm²

Koulè-kodaj ak dimansyon tib nan DIN 46228, pati 4 (0.5 ~ 50mm²)

Halide gratis, ignifuge flanm dife ka aksepte

Rezistan chalè a 105 ℃ (PP) 120 ℃ (PA)

Materyèl:

99% Copper pi bon kalite

Sentetik: Polypropylène (PP), Polyamid (PA)

Sifas

Fèblan pou pwoteje kont korozyon

Enfòmasyon sou lòd

Kounye a tou disponib nan bwat plastik sou la men pou pi piti kondisyon.Nan sikonstans nòmal nou pa gen MOQ egzijans pou anbalaj sak.

Done teknik

Materyèl kondiktif (eksepte Quick Connect Range)

| Kwiv | 99.9% pi |

| Fòs rupture | 200MPa |

| Ductile Rating | 35% |

| Eta metal final | Pati nan pwodwi a rkwit |

| Kontni oksijèn | 50ppm max |

|

|

|

| Kwiv | 30% Zenk 70% Copper |

| Fòs rupture | 580 Mpa |

| Ductile Rating | 6% min |

| Eta metal final | Pati nan pwodwi a rkwit |

|

|

|

| Materyèl | Eten |

| Eten kontni | 99.90% |

| Lòt metal yo | Plon + Antimwàn |

| Plating epesè | 1.5 mikron |

|

|

|

| Jeneral konduktivite | 98.5% IACS |

| Rezistivite total | 1.738 mikwo-ohm cm |

|

|

|

| Materyèl | PVC pou tout eksepte nilon 6 oswa nilon 66 - pou IQC |

| Pann vòltaj | 1.5 k V (min) |

| Rezistans izolasyon | Pi wo pase 100 mega ohms |

| Travay vòltaj | Jiska 300V AC/DC |

|

|

|

| Pre-Izole | -40℃ pou +150℃ |

| Kwiv | 145℃ |

| Fèblan plake | 160℃ |

SPESIFIKASYON

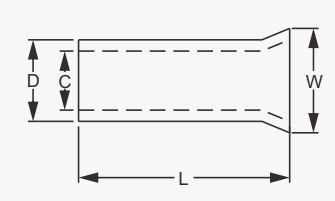

| Seksyon kwa (mm²) | Atik No. | Dimansyon (mm) | AWG |

| Seksyon kwa (mm²) | Atik No. | Dimansyon (mm) | AWG | ||||||

| L | W | D | C |

| L | W | D | C | ||||||

| 0.25 | EN0206 | 6 | 1.5 | 1.1 | 0.8 | #26 |

| 10 | EN10-18 | 18 | 5.8 | 4.9 | 4.5 | #8 |

| EN0208 | 8 |

| EN10-20 | 20 | ||||||||||

| 0.34 | EN0306 | 6 | #24 |

| EN10-25 | 25 | ||||||||

| EN0308 | 8 |

| 16 | EN16-12 | 12 | 7.2 | 6.2 | 5.8 | #6 | |||||

| 0.5 | EN0506 | 6 | 1.7 | 1.3 | '1.0 | #22 |

| EN16-16 | 16 | |||||

| EN0508 | 8 |

| EN16-18 | 18 | ||||||||||

| EN0510 | 10 |

| EN16-20 | 20 | ||||||||||

| EN0512 | 12 |

| EN16-22 | 22 | ||||||||||

| 0.75 | EN7506 | 6 | 1.9 | 1.5 | 1.2 | #20 |

| EN16-25 | 25 | |||||

| EN7508 | 8 |

| 25 | EN25-12 | 12 | 9.1 | 7.9 | 7.5 | #4 | |||||

| EN7510 | 10 |

| EN25-16 | 16 | ||||||||||

| EN7512 | 12 |

| EN25-18 | 18 | ||||||||||

| 1.0 | EN1006 | 6 | 2.2 | 1.7 | 1.4 | #18 |

| EN25-22 | 22 | |||||

| EN1008 | 8 |

| EN25-25 | 25 | ||||||||||

| EN1010 | 10 |

| 35 | EN35-16 | 16 | 10.2 | 8.7 | 8.3 | #2 | |||||

| EN1012 | 12 |

| EN35-20 | 20 | ||||||||||

| EN1018 | 18 |

| EN35-25 | 25 | ||||||||||

| 1.5 | EN1508 | 8 | 2.5 | 2.0 | 1.7 | #16 |

| 50 | EN50-12 | 12 | 12.7 | 10.9 | 10.3 | #1 |

| EN1510 | 10 |

| EN50-18 | 18 | ||||||||||

| EN1512 | 12 |

| EN50-22 | 22 | ||||||||||

| EN1518 | 18 |

| EN50-25 | 25 | ||||||||||

| 2.5 | EN2506 | 6 | 3.3 | 2.6 | 2.3 | #14 |

| 70 | EN70-22 | 22 | 15.8 | 14.3 | 13.5 | 2/0 |

| EN2508 | 8 |

| EN70-25 | 25 | ||||||||||

| EN2510 | 10 |

| EN70-32 | 32 | ||||||||||

| EN2512 | 12 |

| 95 | EN95-25 | 25 | 17.3 | 15.6 | 14.8 | 3/0 | |||||

| EN2518 | 18 |

| EN95-30 | 30 | ||||||||||

| 4 | EN4009 | 9 | 3.9 | 3.2 | 2.8 | #12 |

| EN95-34 | 34 | |||||

| EN4012 | 12 |

| 120 | EN120-30 | 30 | 20.2 | 17.7 | 16.7 | 4/0 | |||||

| EN4018 | 18 |

| EN120-34 | 34 | ||||||||||

| 6 | EN6010 | 10 | 4.7 | 3.9 | 3.5 | #10 |

| EN120-38 | 38 | |||||

| EN6012 | 12 |

| 150 | EN150-32 | 32 | 23 | 20.6 | 19.6 | 250/300 | |||||

| EN6018 | 18 |

| EN150-40 | 40 | ||||||||||

| 10 | EN10-12 | 12 | 5.8 | 4.9 | 4.5 | #8 |

| 185 | EN185-32 | 32 | 23.9 | 21.4 | 20.2 | 300/350 |

| EN10-16 | 16 |

| EN185-40 | 40 | ||||||||||